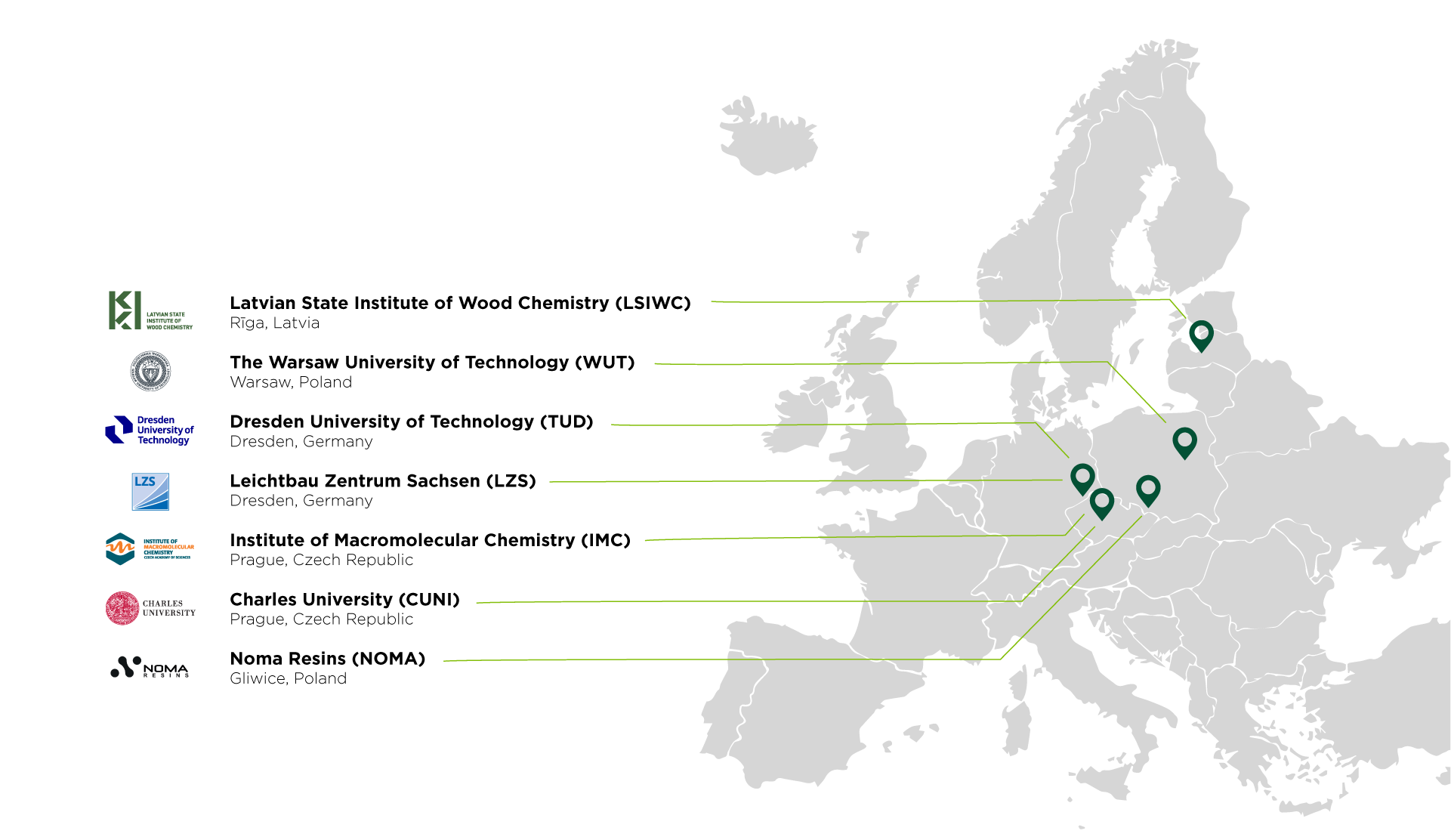

This ambitious three-year project is made possible by a strong international consortium that consists of seven partners – two research institutions (LSIWC from Latvia and IMC from Czech Republic), two SMEs (Noma Resins sp.zo.o. from Poland and LZS GmbH from Germany) and three higher education institutions (CUNI from the Czech Republic, WUT from Poland and TU Dresden from Germany).

Latvian State Institute of Wood Chemistry (LSIWC) is a State Research and Development Institute providing research and testing in the field of wood and wood component chemistry and technology, polymer chemistry and biotechnology; applied studies for obtaining innovative products and materials from renewable raw material resources – wood and plant biomass. The mission of LSIWC is the development of knowledge intensive, environment friendly low-waste technologies for obtaining competitive materials and products from wood and other plant biomass for sustainable utilization of natural resources for economic, social and ecological benefits.

Main expertise and activities:

The Polymer Laboratory at the LSIWC is a leading research centre in the Baltic region in the field of thermoset polymers, with more than 55 years of continuous expertise. The laboratory has a strong track record in the synthesis of bio-based monomers and the development and characterization of advanced polymeric materials. Its research activities are organized into three main directions:

- Bio-based polyurethane (PU) foams – focusing on the formulation and performance optimization of PU materials derived from sustainable feedstocks, including first-, second-, and third-generation bio-based resources as well as bio- and plastic waste streams.

- Cryogenic insulation materials – specializing in the development of rigid PU foam systems designed for low-temperature applications, particularly for use in the aerospace industry and liquified natural gas transportation.

- Bio-based thermoset resins and vitrimers – advancing novel thermosetting systems with dynamic covalent networks for enhanced recyclability, durability, and environmental sustainability.

Role in the project:

LSIWC will be the BioCAN project coordinator and be responsible for project management and coordination. LSIWC will develop bio-based acrylates (acceptor) and amines (donor) from UCO in WP1 and recyclable highly cross-linked β-amino polymer resins (vitrimers) in WP3 from these components that will be used by WUT, TUD, LZS and Noma for composite development applied in the automotive and transportation industry. LSIWC will upscale donor and acceptor component synthesis methods in a 50L pilot-scale reactor to reach TRL5 at the end of the project. LSIWC will contribute to the development of the vitrimers composite recycling technology development and perform the LCA (WP6).

WUT is ranked 1st in Poland among technical universities, and the Faculty of Materials Science and Engineering is one of the leading research and teaching centres in materials engineering, with long-term cooperation with the industry and extensive experience in implementing research projects, including composites, and giving them functional properties.

Contact: Warsaw University of Technology

Main expertise and activities:

The Faculty of Materials Science and Engineering, Warsaw University of Technology, is one of the leading research and teaching centres in the field of materials engineering both in Poland and Europe. The specificity of the Faculty is the interdisciplinary nature of research, including issues of physics, chemistry, and biology. The work carried out is focused on the relationships between macro-, micro- and nanostructure and the properties of materials used in various industries, including aviation, automotive and renewable energy. The faculty has advanced and unique research equipment, which enables a comprehensive approach to testing the properties of polymer composites and evaluating samples at every stage of manufacturing or modification. The "Polymer Composites" group has extensive knowledge in the field of designing and assessing the effectiveness of flame retardant systems based on renewable raw materials.

Role in the project:

WUT will be responsible for the development and manufacturing bio-based flame retardant systems to manufacture vitrimer resin with reduced flammability. Moreover, WUT will assess the flammability of manufactured composites using standard laboratory methods such as the UL-94 test , Pyrolysis Combustion Flow Calorimetry (PCFC), and Fourier-transform infrared spectroscopy coupled with thermogravimetric analysis (TGA/FT-IR).

The Institute of Lightweight Engineering and Polymer Technology (ILK) of TUD Dresden University of Technology (TUD) is the internationally acknowledged institute for research, development and student training in the area of function-integrative system lightweight engineering in multi-material design. At the ILK a comprehensive approach is pursued with respect to both materials and products throughout the total engineering chain - material, design, simulation, manufacturing, component, quality assurance.

Contact: Institute of Lightweight Engineering and Polymer Technology (ILK). Technische Universität Dresden

Main expertise and activities:

The ILK team’s core competence is in the development, design and optimisation of components and systems in high performance lightweight construction as well as in prototype manufacturing. According to the Dresden model of “function-integrative system lightweight engineering in multi-material design”, mixed construction holds a central position.

The institute’s expertise is reflected in a plethora of different interdisciplinary joint research projects with ILK as initiator and speaker. The knowledge gained through fundamental studies is integrated into the development of innovative lightweight structures and associated manufacturing processes through to the readiness for series production.

Role in the project:

In BioCAN, the Institute of Lightweight Engineering and Polymer Technology (ILK) is responsible for the development and validation of high-performance, bio-based vitrimer composites for industrial applications.

For this, the ILK is contributing its expertise in process modelling and simulation, development of efficient manufacturing processes, manufacturing and testing of demonstrators, and LCA analyses for techno-ecological system assessment.

Engineering and testing in the loop since 2003. The LZS provides both engineering and testing services to fuel a simulation driven and test backed design approach in a complex engineering world.

Contact: LZS GmbH

Main expertise and activities:

With a strong background in plastics, we provide the whole development chain from feasibility studies, concepts, design, and prototyping with accompanying tests covering coupons, substructures and whole assemblies.

Role in the project:

Testing of fiber-reinforced plastics and resins based on vitrimers. Regarding the standards established for testing polymers, we conduct the entire range of basic characterization, including thermodynamic, physical, and mechanical testing.

The Institute of Macromolecular Chemistry, Czech Academy of Sciences (IMC), is an internationally recognised research and educational organisation in the field of synthetic polymers. Its mission is advancing the area of macromolecular chemistry, organic chemistry, macromolecular physical chemistry and macromolecular physics including their related interdisciplinary fields with the purpose of acquiring knowledge about relations between structure, properties and function of macromolecular systems and about controlled creation of supramolecular structures.

Contact: Institute of Macromolecular Chemistry, Czech Academy of Sciences

Main expertise and activities:

Our research is oriented on the development of new synthetic and technological processes, on new polymer materials and their applications as well as on design of polymers for electronics, for medicinal chemistry and for tissue engineering including investigation of interactions of biological systems with polymeric materials. The combination of interdisciplinary teams of knowledgeable experts with up-to-date experimental facilities is the main asset of the Institute. Although the Institute is primarily focused on fundamental research, it also closely cooperates with the application sphere. This is particularly true for application of polymers in medicine, but also for material research and for assessment of the ecological impact of plastic waste. The Institute provides training in polymer science for postgraduate, graduate as well as undergraduate students enrolled at Czech universities. It also traditionally runs international postgraduate courses in polymer science under the auspices of UNESCO and IUPAC.

Role in the project:

IMC will participate in the synthesis of starting components for vinylogous urethane thermosets (WP2) and will coordinate WP3 (preparation of vitrimers). Particularly, IMC will be responsible for developing bio-based vinylogous urethane vitrimers (WP3, Task 3.2) that will be further used by WUT, TUD, LZS and Noma for composite development. IMC will provide analytical support for the developed material characterization in WP1. IMC will also participate in WP5 (recycling of vitrimer composites).

The Faculty of Science, Charles University (CUNI), is a leading academic and research institution in the Czech Republic, with a strong international reputation in the fields of chemistry, biology, geology, and environmental sciences. The Department of Physical and Macromolecular Chemistry, where the project activities will be carried out, specializes in polymer synthesis, advanced macromolecular characterization, and the development of novel polymeric materials. The faculty combines fundamental research with applied projects and maintains close collaboration with industry and international partners.

Contact: Charles University

Main expertise and activities:

Our research in polymer chemistry focuses on controlled/living polymerization techniques, design of functional polymers, self-assembly of macromolecules, and development of materials for biomedical, catalytic, and environmental applications. In particular, we have extensive expertise in the synthesis of biobased and stimuli-responsive polymers, vitrimers, and dynamic covalent networks. We also provide advanced structural, thermal, rheological, and mechanical characterization of polymeric materials. Our laboratory is equipped with state-of-the-art facilities for monomer synthesis, polymerization, and analysis, enabling us to cover the full development pathway from molecular design to final material performance testing.

Role in the project:

CUNI will be responsible for the design, synthesis, and characterization of novel biobased monomers to be used in vinylogous urethane vitrimer formulations (WP2). The prepared monomers will be supplied to project partners for vitrimer synthesis and composite preparation, in particular within WP3. CUNI will also contribute to the physico-chemical characterization of intermediate and final materials (WP1) and support recycling studies within WP5

NOMA is a SME from Poland which specialize in the production of resins, in particular epoxy resins based on bio components. Our offer also includes auxiliary materials necessary in the technological process of composite production. NOMA produces among others prepregs which do not need decreased temperatures for handling as well as SMC/BMC materials (also with recyclates) and composite elements based on recycled materials for e.g. for public transport and UAVs.

Contact: Noma Resins sp.zo.o.

Main expertise and activities:

NOMA’s past experience in development of the resins and fabrication the composites based on the recycled materials is the result of participation of other EU founded projects including MC4 project: Multi-level Circular Process Chain for Carbon and Glass Fibre Composites, Biostruct and Biosafire projects: Manufacturing process for bio-based fibre-reinforced composite parts for structural applications as well as Polish–Norwegian sustainable research and innovation ecosystem for improving composites’ waste management and recyclability (“GREEN-COMP”).

Role in the project:

NOMA will be the leader of WP6, which will focus on developing recycling strategies for both matrices and fibers used in the vitrimer-based composites. Their expertise in the mechanical recycling of thermoset composites will be utilized to explore effective grinding processes for obtaining well-characterized fractions of fibers and resin. NOMA, as an industrial partner, will provide its industrial expertise by providing specific requirements or constraints that need to be taken into consideration during vitrimer component synthesis in WP1 and WP2 to fine-tune the properties of end components.